URAW-P657

Hybrid Film Capacitor Winder

With the unique amalgamation of expert professionals and technology friendly approaches, our company has placed ourselves as a reliable name in the Winding Machine markets. For more information about our high quality standards Hybrid Film Capacitor Winder, please contact with us in anytime.

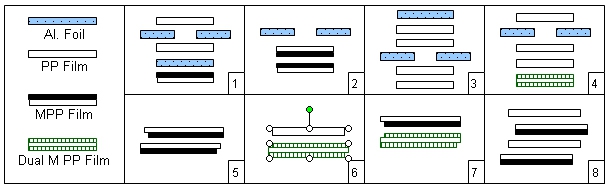

This series are particularly designed for mixed producing of Metallized Film Capacitor and Non-Inductive Foil Capacitor, which has efficacy of series capacitor and power capacitor. It can wind Standard Capacitor, Non-Inductive Foil Capacitor, Foil Series Capacitor and Metallized Film Plus Foil Series Capacitor.

The following winding structures are for reference.

This series are particularly designed for mixed producing of Metallized Film Capacitor and Non-Inductive Foil Capacitor, which has efficacy of series capacitor and power capacitor. It can wind Standard Capacitor, Non-Inductive Foil Capacitor, Foil Series Capacitor and Metallized Film Plus Foil Series Capacitor.

The following winding structures are for reference.

- Equipped with independent transmission structure, main winding and outer seal could be running independently, save the winding time.

- Two mandrels rotating to assure short cycle time.

- Tension controlled by DC servomotor; main winding by AC servomotor, speed stably, long life.

- The outer seal uses the digit display PID control (PID control ±1%).

- Inner seal and outer seal controlled by individual thermostat, the products have good appearance.

- Process control system by PLC system and Pro-Face 10.4” monochrome monitor, it can memorize 60 sets of specification, easy to change production specification.

- Automatic indication function for self-examining breakdown. When machine breakdown, it can self- testing to find reason and show the situation on the screen. It’s able to record the breakdown time.

- Speed up/down rate setting functions, excellent for high current, high voltage and interference suppressors class X2 capacitor.

- With electronic burn off control system, speed adjustable and suitable for Al. or Zinc/Al. metallized layer, the de-metallizing effect is very good.

- Equipped with Dual Side Winding function, the machine suits the double side metallized film.

- Equipped with impression roller.

| Mandrel Size | f 3, 4, 5, 6, 8, 9 mm. | |

| Mandrel Reel / Effective Mandrel Length | 2 Reels / 50 mm | |

| Material Reel | 7 Reels | |

| Metal Film | ID / OD | f40mm / f180mm |

| Thickness / Width | 5~12mm / 5~40mm | |

| Hang Method | Press Buckle Type | |

| PP Film | ID / OD | f75mm / f180mm |

| Thickness / Width | Min. 3mm / 5~45mm | |

| Hang Method | Press Buckle Type | |

| MPP Film | ID / OD | f75mm / f180mm |

| Thickness / Width | Min. 3.5mm / 5~45mm | |

| Hang Method | Press Buckle Type | |

| Burn Off Foil | Number of Reel | 3 Sets |

| ID / OD | f40mm / f150mm | |

| Thickness / Width | 18~25mm / 60mm | |

| Burn Off Unit | 3 Sets | |

| Cut-Press Foil Unit | 2 Sets | |

| Element Size (OD) | Max. f70mm | |

| Capacitance Control | Turns Controlled | |

| Single Pressure Roller | Air Adjustment: 0~2 kg/cm2 | |

| Memory Quantity | 60 Sets | |

| Sequential Control | PLC Control System | |

| Tension Control | DC Servo Motor Controlled, Air Adjustment : 0~500g | |

| Seal Winding | Digit Display, PID Controlled ±1% | |

| Winding Speed | Max. 4500 R.P.M. | |

| Power Source | AC220V 1f 50/60Hz 1.5KVA | |

| Air Pressure | 5 kg/cm2 | |

| Machine Size | L1300mm ’ W1020mm ’ H1745mm | |

| Machine Weight | About 500KGS | |

| Related Model | Standard Model | URF-P407 |

| With Cover Film Model | URF-P407-C | |

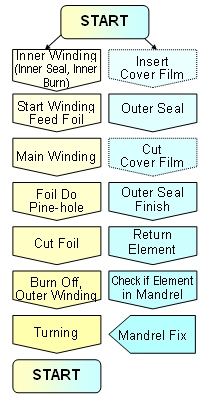

FLOW CHART