WORLDWIDE

Home / Product Line

Capacitor Winding Machines for Metallized Film Capacitor

Over the years, UNITRONIC AUTOMATION CO., LTD. achieved continuous growth by closely observing the market in order to produce customer-oriented products. Our For Metallized Film Capacitor is made to the same rigorous quality standards that our commercial customers demand. With the help of For Metallized Film Capacitor, you can easily manage and track your business. Our aim is to create a strong base for the consumers and suppliers in Taiwan and abroad, through which, a perfect chain of demand and supply can be maintained. Our company is a professional manufacturer of For Metallized Film Capacitor, providing URM-60CB-PP, For Metallized Film Capacitor, Metallized Film Capacitor with top quality.

URM-60CB-PP

For Metallized Film Capacitor

- Two mandrels rotating to assure short cycle time.

- Tension controlled by DC servomotor; main winding by AC servomotor.

- The outside seal uses the digit display PID control (PID control ±1%

- Process control system by IPC 586 computer, with hard disk to memorize 600 sets of specification,easy to change production specification.

- It has 3.5” disk driver, which is able to correct process and backup them.

- Automatic indication function for self-examining breakdown. When machine breakdown, it can self-testing

- to find reason and show the situation on the screen. It’s able to indicate the inspection and repairable methods.

- Speed up/down rate setting functions, excellent for high current, high voltage and interference suppressors class X2 capacitor.

- With electronic burn off control system, speed adjustable and suitable for Al. or Zinc/Al. metallized layer, the de-metallizing effect is very good.

- Main winding up to 9000 R.P.M

- With prepress structure, the element will be received and press by the unloading unit after the winding

- Metallized film and PP/PE material reels are equipped tracing roller. As the material’s OD changes, the

- position of tracing roller will be changed too. They won’t touch the material.

- It could select to use cover film function or not by program control.

- Air cylinder of low friction for dancer rollers and pressure roller with hand adjustment.

TEST STEP :

| Mandrel Size | f 3, 4, 5, 6,7,8mm | |

| Metal Film | Thickness | Min. 3mm |

| ID | f75mm | |

| OID | f240mm | |

| Dual Winding | 8~27mm | |

| Single Winding | 8~50mm | |

| Al. Foil Burn Off | Thickness | 20mm ’ 60mm |

| ID | f 38~40mm | |

| OD | f150mm | |

| Number | 2 sets | |

| Element Size (OD) | Max. f28mm | |

| Element Size (OD) | Max. 9000 R.P.M. | |

| Capacitance Control | Turns Controlled | |

| Memory Store | 600 sets | |

| Sequential Control | I.P.C. Controlled | |

| Tension Control | DC Servo Motor Controlled | |

| Seal Winding | Digit Display, PID Controlled ±1% | |

| Power Source | AC220V 1f 50/60Hz, 1.5 KVA | |

| Air Pressure | 5 kg/cm2 | |

| Machine Size | L1050mm ’ D950mm ’ H1780mm | |

| Machine Weight | About 500 KGS | |

Other :

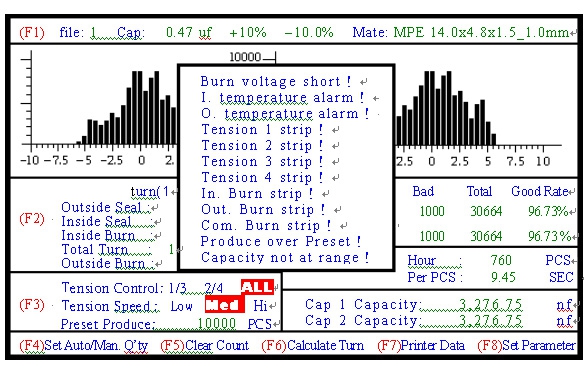

DISPLAY SCREEN

Our products have always been known for quality, reliability and solid performance, making UNITRONIC AUTOMATION CO., LTD. becomes the most specified brand in the For Metallized Film Capacitor business. We can manufacture For Metallized Film Capacitor that meets specific technical requirements. If you are looking for URM-60CB-PP, For Metallized Film Capacitor, Metallized Film Capacitor, Film Capacitor, you are in the right place. At UNITRONIC AUTOMATION CO., LTD., you will find every kind of For Metallized Film Capacitor that you can think of, with something for all kind of business.