WORLDWIDE

Home / Product Line

Capacitor Winding Machine | For Metallized Film Capacitor

UNITRONIC AUTOMATION CO., LTD. designs and manufactures For Metallized Film Capacitor that complies with the most stringent operating requirements. Furthermore, we provide customized solutions to our clients based on their demands and assure the delivery of all consignments within the promised time-frame. Based on our long manufacturing experience in developing new products, our company possesses the capability of manufacturing a wide range of For Metallized Film Capacitor and is able to cater to the unique needs of our customers. Please visit any of our great locations to see the latest products from manufacturers like URM030-50-60PP, For Metallized Film Capacitor, Metallized Film Capacitor and many more!

URM030-50-60PP

For Metallized Film Capacitor

- Two mandrels rotating to assure short cycle time.

- Tension controlled by DC servomotor; main winding by AC servomotor.

- The outside seal uses the digit display PID control (PID control ±1%).

- The products have good appearance.

- Process control system by IPC 586 computer, with hard disk to memorize 600 sets of specification, easy to change production specification.

- It has 3.5” disk driver, which is able to correct process and backup them.

- Automatic indication function for self-examining breakdown. When machine breakdown, it can

- self-testing to find reason and show the situation on the screen. It’s able to indicate the inspection and repairable methods.

- Speed up/down rate setting functions, excellent for high current, high voltage and interference suppressors class X2 capacitor.

- With electronic burn off control system, speed adjustable and suitable for Al. or Zinc/Al. metallized layer, the de-metallizing effect is very good.

- Main winding up to 9000 R.P.M

- With prepress structure,the element will be received and press by the unloading unit after the winding

TEST STEP :

| Machine Model | URM-30-PP | URM-50-PP | URM-60-PP | |

| Mandrel Size | Ø (2, 3 mm)*2pcs | Ø2,5, 3, 4, 5,6 mm | Ø3*2pcs, 4, 5, 6 mm | |

| Metal Film | Thickness | MPE min 2 mm MPP min 3.5mm |

MPE min 3 mm MPP min 4mm |

|

| OD / ID | Ø240mm /Ø75mm | |||

| Dual Winding | 4.5~14mm | 7.5~21mm | 9~26mm | |

| Reel Quantity | 4Reels | |||

| Al. Foil Burn Off | Thickness | 20μm | ||

| Width | 30mm | 50mm | 60mm | |

| OD / ID | Ø150mm / Ø38~40mm | |||

| Reel Quantity | 2 Sets | |||

| Element Size (OD) | Max Ø18mm | Max Ø27mm | Max Ø27mm | |

| Effective Mandrel | 35mm | 50mm | 60mm | |

| Capacitance Control | Turns Controlled | |||

| Memory Store | 600 Sets | |||

| Sequential Control | I.P.C. Controlled (586CPU) | |||

| Tension Control | DC Servo Motor Controlled | |||

| Tension gw system | 15gw~200gw/Air Cylinder System | |||

| Touch roller system | 200gw~2000gw/Air Cylinder System | |||

| Pre-pressing mechanism system | Prepressing unit has two times,first low pressure,second high pressure | |||

| Seal Winding | Digit Display, PID Controlled ±1% | |||

| Power Source | AC220V 1Ø50/60Hz 1.5KVA | |||

| Air Pressure | 5 kg/cm² | |||

Other :

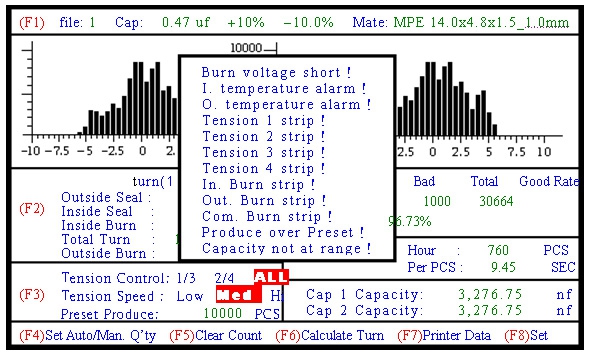

DISPLAY SCREEN

UNITRONIC AUTOMATION CO., LTD. recognizes our customers have different needs, and we want to help you find the perfect For Metallized Film Capacitor from our wide selection of styles and designs. Our company is one of the main producers of For Metallized Film Capacitor in machinery & industrial supplies and is highly regarded for quality products. We achieve our goals through dedicated associates performing the highest quality workmanship, which in turn allows us to supply our customers with the best products and services. Please feel free to contact us if you have any inquiries or problems.