WORLDWIDE

Home / Product Line

Automatic Metal Spraying Machine | Supplier from Taiwan

Our company is a well-known manufacturer of premium grade Automatic Metal Spraying Machine in Taiwan. UNITRONIC AUTOMATION CO., LTD.'s team is second to none. With our extensive experience, we have successfully attained a remarkable position in the market. Furthermore, our knowledge, energy, and passion ensure you achieve the best possible outcome for your customers. We wish to create win-win relationships throughout the supply chain. It is our pleasure to service your Automatic Metal Spraying Machine needs. UNITRONIC AUTOMATION CO., LTD. is committed to providing quality LSSP-500A, Automatic Metal Spraying Machine, Spraying Machine to our customers. You should receive a response within 24 hours. If you have any special requests or are looking for an item you could not find, please fill out the Contact Us form and it will be forwarded to the correct department.

LSSP-500A

Automatic Metal Spraying Machine

Innovative design, durability, high performance, and low maintenance requirement are the features of our Automatic Metal Spraying Machine. If you want to know more relative information about Metal Spraying Machine, please contact us immediately.

The Metal Spraying is a very critical operation in the manufacture processes of metallized film capacitor. Since the metal particles are produced by wire melted and high velocity to coat in the end faces, it makes contact with the capacitor winding primarily by partial penetration of the pockets in the end faces formed by staggering the films. Factors which affect the degree of penetration are mainly the velocity of the metal spray particles and their size. So the following important factors are influential capacitors quality: The temperature of metal spray particles, the size of metal spray particles, the velocity of metal spray particles, the average of metal spray particles

Incorrectly selected spray equipment can cause severe damage to end faces of the windings and produce unacceptably high power factor capacitors. The AUTOMATIC METAL SPRAYING MACHINE is designed through our comprehensive research and accumulated ten-year of experience; as the requirements of regarding above specially performance of metal spraying in metallized film capacitor.

The Metal Spraying is a very critical operation in the manufacture processes of metallized film capacitor. Since the metal particles are produced by wire melted and high velocity to coat in the end faces, it makes contact with the capacitor winding primarily by partial penetration of the pockets in the end faces formed by staggering the films. Factors which affect the degree of penetration are mainly the velocity of the metal spray particles and their size. So the following important factors are influential capacitors quality: The temperature of metal spray particles, the size of metal spray particles, the velocity of metal spray particles, the average of metal spray particles

Incorrectly selected spray equipment can cause severe damage to end faces of the windings and produce unacceptably high power factor capacitors. The AUTOMATIC METAL SPRAYING MACHINE is designed through our comprehensive research and accumulated ten-year of experience; as the requirements of regarding above specially performance of metal spraying in metallized film capacitor.

FEATURE :

- By using DC electric ARC system, sprayed metal particle is very fine and strongly adhered to film surface which enables you to produce high qualified uniform capacitors.

- Closed shut system can improve the working environment wth no noise and no dust in the metal spray room.

- 3 reels turn table and 2 guns system enables non-stop operation:

Elements Setting → Shutter Open → Elements In and Finished Elements Out → Shutter Close →

Gun Move → Elements Turn → Air Shower → Spray Start → Spray End → Air Shower → Shutter Open.

- Elements setting apparatus enables safe elements input and avoid products damage.

- Each gun can set the numbers of spray times and by using the in-built program of different turning

R.P.M. between border and center of disk, metal sprayed thickness is very uniform at any point.

- Gun is operating only when the elements disk is arrived at spray position and it can save material consumption.

- Spray distance can be adjusted by remote control system in order to get the best spray condition.

TEST STEP :

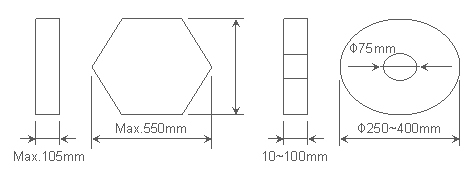

| Ment Disk Size | Dia.: Max .550mm Thickness: Max. 105mm Disk Speed: 15~60 R.P.M. (Adjustable)  |

|

| Spray Wire Material | Zinc, Lead, Tin Lead, Tin Copper, etc. | |

| Spray Wire Dia. | Ø1.6~2 mm | |

| Wire Feeding Speed | 0~7000 mm/Min. (Adjustable) | |

| Spray Distance | 150~350 mm (Adjustable) | |

| Spray Productivity | Within 3.5 Min / 4 Times spray on 1 side | |

| Spray Electricity | Input Power | AC 380V Ø3 20KVA |

| Output DC Voltage | 18~30V | |

| Output Current | Max. 200A | |

| Air Pressure | 1st Gun | 7 kg/cm2 |

| 2nd Gun | 4.5~5 kg/cm2 |

|

| Consumption | Min. 3 m3 | |

| Layer Thickness | 1st Layer: 0.30~0.35 mm (Adjustable) 2nd Layer: 0.23~0.28 mm (Adjustable) |

|

| Machine Dimension | L2700 x W2000 x H2250 mm | |

| Machine Weight | About 750 kgs | |

UNITRONIC AUTOMATION CO., LTD. provides Automatic Metal Spraying Machine of the highest quality with focus on flexible solutions, reliability and customer understanding. Our company is a professional manufacturer of Automatic Metal Spraying Machine, specializing in providing Automatic Metal Spraying Machine with superior quality. To reach many people, our products must be of good quality and affordable. We design with our customers’ needs in mind. We are committed to understanding our customer's business to provide true commercial value in our operations.